|

|

General Information

Vulcan is a small precision Engineering Company

specialising

in

rifle barrel manufacture and deep hole drilling. Deep hole drilling is

where the depth to diameter ratio is greater than 10 and up to 200.

Deep hole drilling has many applications in Industry; from Engine

Camshafts and oil pressure manifolds to many Hydraulic applications;

with Straightness tolerance of .001" (.025mm) per foot

typically

and fine internal finish up to 4Ra.

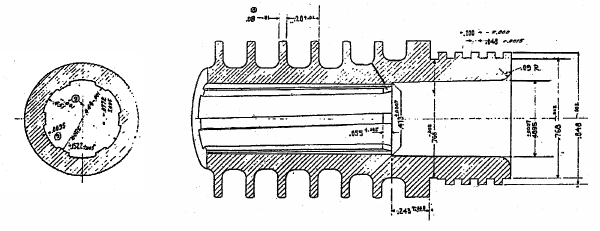

Vulcan has been developing rifle barrel manufacture over the past few years and now can offer a range of barrel calibres and profiles; mainly from 4140 Chrome Molydenum Steel and 416 Stainless steel. The barrel steel used is supplied as a Certified Standard and is tested for strength and Non Destructively Tested for flaws. Mill Certificates and material Test Results are available on request.

The rifling (spiral grooves to impart spin to the bullet) is swaged into the drilled and honed cylindrical bore with a carbide 'Button', drawn through the bore at a defined 'Twist' or revolutions per foot, to suit the length of the bullet for a certain calibre. (Longer bullets have to spin faster than shorter bullets of the same calibre, to obtain stability and thus accuracy at the target.)

There is an argument raging in the rifle shooting world over 'Buttoned' barrels verses 'Cut' rifled barrels. Almost 99% of all rifle barrels produced today are 'Buttoned'. With good process controls, both types of manufacture yield similar results. The 'Cut' barrels running twice to three times more expensve to produce. Vulcan can supply cut barrels for those special 'one off' restoration Jobs where the barrel is an odd size and/or has a unique rifling form, or where the swaging process is not an option. Vulcan produce only the barrel blank, and not the whole gun, so these parts do not constitute a gun part and are exempt the usual export and mailing hassles.

Barrels

- Most calibers and twists (.22 to .50 calibre, including 9mm para, .338 Lapua, .45 ACP, .45 L.C., 45-70 and .50 BMG).

- Cut rifling and octagonal external shapes.

- Fitting and blueing services available.

- Standard contours, others available.

- Material Test Certificates.

- M16 'drop In' exchange barrel units (supply old barrel for exchange, locking piece and gas block re-fitted).

- Barrels stress relieved and lapped.

- Shaft diameter 50mm maximum

- 1,000mm (40") maximum depth

- 3mm (0.125") drill up to 25mm (1")

- Hydraulic and industrial applications

Prices

Available upon request.

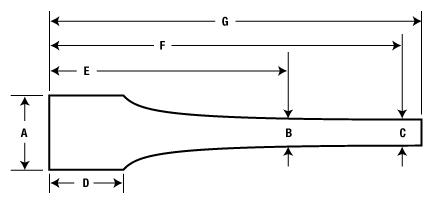

Profiles

|

|

Dimensions |

|

Contour # |

A |

B |

C |

D |

E |

F |

G |

Weight

at |

|

1

Featherweight |

1.250 |

.700 |

.550 |

2.5 |

6 |

20 |

22 |

2 lbs 10oz. |

|

2

Lightweight |

1.250 |

.765 |

.575 |

2.5 |

6 |

24 |

26 |

3 lbs 3oz. |

|

3

Sporter |

1.250 |

.815 |

.625 |

2.5 |

6 |

24 |

26 |

3 lbs 7oz. |

|

4

Magnum Sporter |

1.250 |

.860 |

.650 |

3.0 |

6 |

26 |

28 |

3 lbs 14oz. |

|

5

Lightweight Varmint |

1.250 |

.910 |

.700 |

3.0 |

6 |

26 |

28 |

4 lbs 8oz. |

|

5

1/2 Medium Weight Varmint |

1.250 |

.960 |

.750 |

3.0 |

6 |

26 |

28 |

4 lbs 14oz. |

|

6

Lightweight Target* |

1.250 |

-- |

.750 |

3.0 |

-- |

26 |

28 |

6 lbs |

|

7

Standard Varmint* |

1.250 |

-- |

.890 |

4.0 |

-- |

26 |

28 |

7 lbs 1oz. |

|

8

Heavy Bull Barrel* |

1.250 |

-- |

1.000 |

3.0 |

-- |

26 |

28 |

7 lbs 12oz. |

| Benchrest Special | Straight

cylinder, 30" long, any diameter from 1.250" to 2.000", 32" maximum finish length (dependant on twist). |

| Straight Barrel | Any

diameter up to 1.250" 32" maximum finish length (dependant on twist). |

* .50 BMG barrels finished at 36" can be supplied chambered.

Contact

For more information on products or ordering procedures contact:

- email - johnreubenthomson@gmail.com

- via mail - Vulcan Rifle Barrels Ltd., P.O. Box 308, Christchurch 8140, New Zealand.